Frequently Asked Questions

Browse common questions by category, or use search to filter.

General Questions

What are Apex Instruments, Inc. hours of operation?

For your convenience, we are open Monday through Friday from 8:00 am until 5:00 p.m. (EST)

What types of payment does Apex Instruments, Inc. accept?

Apex Instruments, Inc. accepts MasterCard, Visa, American Express and wire transfer. Company purchase orders are acceptable upon credit approval.

How quickly can I receive my order?

Most stock item orders are shipped within 24 hours of receipt. Please allow extra time for custom orders. Shipping times vary according to the requested shipping service. If you have questions about your shipment please email our shipping management at shipping@apexinst.com.

How can I be approved for company credit?

To request a credit application, please fill out an Information Request Form or email accounting@apexinst.com. Please allow for processing time.

How do I request a product catalog?

For fast information, please visit our Product Area, where a full list of products is represented. Additionally, feel free to download a copy of the catalog in the Catalog page, which can be found in the Support top menu tab.

How do I find a complete list of part numbers and or kit configurations?

Apex Instruments has over 10,000 parts, we find it best to talk with our sales department to quickly help you. Please contact sales at sales@apexinst.com

Does Apex Instruments, Inc. have international distributors?

Do I need an RMA (Return Merchandise Authorization) to return items I have purchased from Apex instruments, Inc.?

Yes. Customers wishing to return items for service or credit need to contact our sales associates for an RMA. Contact support@apexinst.com / phone (919) 557-7300 or use the Contact Us form. Please allow for processing time.

Does Apex Instruments provide a product price list?

(WIP) How do I find your kit configurations?

Here is a link to our Apex Instruments Kit Configurator.

How long is an Apex Instruments quote valid? Can I make changes to my order after it’s been quoted?

Quotes from Apex Instruments are valid for 60 days. If your order is not placed within this timeframe, you will need to request a new one. If you need to update your quoted order, please contact our Sales Department, sales@apexinst.com, and an updated quote will be given to you. It would be helpful if you list the quote number in your email.

(WIP) What are the Terms and Conditions of Apex Instruments?

You may read our entire Terms and Conditions on our website here.

(WIP) Is there proof that benzoic acid is a byproduct of the degradation of XAD-2?

We do have several years of data showing that benzoic acid is a degradation product of the XAD-2 when exposed to stack gases. Please refer to the answer to [Benzoic acid, at high concentrations, has appeared in my field blanks, trip blanks, and samples using SW-846, Method 0010. Is benzoic acid real or a breakdown product of XAD-2 resin?] for an explanation of the weaknesses of XAD-2 and how to minimize background contamination of XAD-2 in your sampling program.

Other Helpful Videos & Tips

Here is a link to our Helpful Videos & Tips Playlist if you’d prefer to watch on YouTube directly.

Feel free to check out our YouTube channel as well if you cannot find the information you’re looking for in this playlist.

Where can I access EPA documents and method information?

The EPA’s documents and information are accessible via their website: www.epa.gov

Here is a list of useful EPA pages for stack testing:

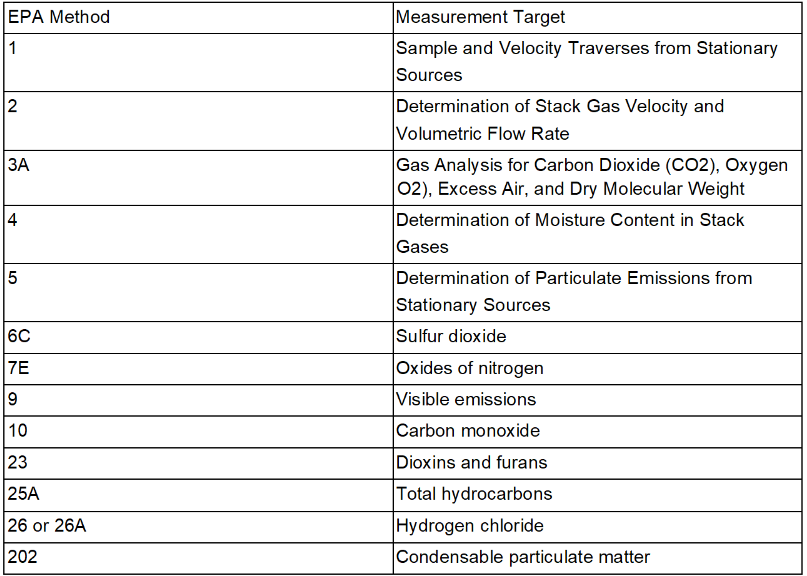

US EPA Test Methods

Promulgated Test Methods: These methods have been proposed or promulgated in the Federal Register and codified in the Code of Federal Regulations (CFR).

Proposed Test Methods: Proposed test methods have been published in the Federal Register as proposed rules, but have not yet been promulgated. Proposed Federal Register Methods maybe new methods or revisions to existing FR Methods. When the method is promulgated, it becomes the official Code of Federal Regulations (CFR) Method.

Approved Alternative Methods: These methods may be used by sources for determining compliance with the requirements of these Parts per their specified applicability provisions without further EPA approval. The Administrator, or designee has approved these methods for the specified applications; this approval has been documented through an official EPA letter. These methods include quality control and quality assurance procedures that must be met. The EPA staff may not necessarily be the technical experts on these methods.

Conditional Test Methods: This category includes methods that were categorized as conditional test methods before our method categories were revised. Because some of these methods have been cited in state rules and permits under their Conditional Test Method (CTM) designation, we have created a category for them and called it ΓÇ£Historic Conditional MethodsΓÇ¥. This category is closed and no new methods will be added to it.

Other Test Methods: This category includes test methods which have not yet been subject to the Federal rulemaking process. Each of these methods, as well as the available technical documentation supporting them, have been reviewed by the Emission Measurement Center staff and have been found to be potentially useful to the emission measurement community.

Monitoring:

Promulgated and Proposed Performance Specifications: Performance specifications are used for evaluating the acceptability of the Continuous Emission Monitoring System (CEMS) at the time of or soon after installation and whenever specified in the regulations.

Quality Assurance Procedures: Quality assurance procedures in Appendix F to 40 CFR 60 are used to evaluate the effectiveness of quality control (QC) and quality assurance (QA) procedures and the quality of data produced by any Continuous Emission Monitoring System (CEMS) that is used for determining compliance with the emission standards on a continuous basis as specified in the applicable regulation.

Compliance Assurance Monitoring: The Compliance Assurance Monitoring, or CAM, rule is designed to satisfy the requirements for monitoring and compliance certification in the Part 70 operating permits program and Title VII of the 1990 Clean Air Act Amendments. The CAM rule includes a new Part 64 and associated revisions to the Part 70 (permits program) monitoring and compliance certification requirements. The rule would establish criteria that define the monitoring, reporting, and record keeping that should be conducted by a source to provide a reasonable assurance of compliance with emission limitations and standards. These criteria address defining the applicable monitoring approach, obligation to complete corrective actions as indicated by the monitoring results, and how such data are used in the annual compliance certification.

Continuous Emission Monitoring: A continuous emission monitoring system (CEMS) is the total equipment necessary for the determination of a gas or particulate matter concentration or emission rate using pollutant analyzer measurements and a conversion equation, graph, or computer program to produce results in units of the applicable emission limitation or standard.

Metals and Mercury Emissions Monitoring

EPA Technical Support

Technical Support for Quality Assurance

EPA Instructional Material

Technical Information Documents

Workshop and Meeting Materials

EPA Volume III PDF Documents

Users are cautioned that neither of these documents have been updated since they were published and that many of the test methods have been revised and program responsibilities changed. Users are also advised that while these documents present procedures and information that are reflective of good practice, the guidance provided in these documents has no legal standing unless the CFR specifically requires the tester to follow Volume III.

What is Method 7C/7D?

Method 7C (Colorimetric) and 7D (Ion Chromatography) are used for the determination of nitrogen oxide emissions.

A sample is passed through a series of specially built impinger that contains an alkaline potassium permanganate solution. The impingers are of standard height with a narrow bottle, which improves the collection efficiency. The sample rate is between 400 and 500 cubic centimeters per minute. Normally, three one-hour samples are collected for the test.

For 7C, an integrated gas sample is extracted from the stack and passed through impingers containing an alkaline potassium permanganate solution; NOX (NO + NO2) emissions are oxidized to NO2 and NO3. Then NO3− is reduced to NO2− with cadmium, and the NO2− is analyzed colorimetrically.

For 7D, an integrated gas sample is extracted from the stack and passed through impingers containing an alkaline-potassium permanganate solution; NOX (NO + NO2) emissions are oxidized to NO3−. Then NO3− is analyzed by ion chromatography.

For more information and documents about Method 7C, please consult the EPA’s Method 7C webpage. For more information and documents about Method 7D, please consult the EPA’s Method 7D webpage.

Apex Instruments offers a Method 7C/7D Sampling System. If interested in Method 7C/7D sampling, Apex Instruments works with our customers to make sure we are providing the correct products for your project and will provide you with a price quote. For any questions about our sampling system, please contact sales@apexinst.com.

Can You Give A Brief History Of Stack Testing?

Emission inventories have long been recognized as a cornerstone of air quality management. Emission inventories are required in order to establish the sources, determine their relative ΓÇÿinsultsΓÇÖ on the ambient air quality and to develop mitigation strategies for the reduction and management of these emissions, among other things. Without a clear realization of the importance, the strengths and limitations of this tool, it is difficult to make intelligent decisions on the overall air quality strategies to be employed.

The early days of formalized federal actions on air quality were delegated to and carried out by the U.S. PHS. The Taft Sanitary Engineering Center in Cincinnati, Ohio had become known for its work in water quality and establishment of water standards, especially in the late 1950ΓÇÖs and early 1960ΓÇÖs. Thus, the Center was an obvious place to give birth to federal studies and other activities related to air quality. This aspect grew through the mid 60ΓÇÖs and continued as the focal point of such activities within its Division of Air Pollution, Bureau of Abatement and Control (direct predecessor of todayΓÇÖs EPA Office of Air Quality Planning and Standards/OAQPS). That office was moved to Durham, then to Research Triangle Park, North Carolina beginning in 1967.

While still in Cincinnati, the Bureau developed studies to determine how to measure and control air pollution, studied health effects, developed model emission reduction programs, public education efforts, Interstate Abatement (enforcement) actions, 4 and carried out a general charge to analyze the problems and find solutions, even though the levels of authority and controls were rather limited, except where interstate commerce and transport of air pollution was an issue. The interstate actions and processes developed to implement those actions resulted in major contributions to fundamental approaches still utilized today. Many of the pioneers of the ΓÇ£scienceΓÇ¥ and processes or procedures we follow today were employed under these efforts. Many of these were hired from (where else but) the South Coast Air District of California.

One of the major chores of this group of officers and civil servants was to establish techniques, measures, demonstrations and other means to put some handles on this ΓÇ£air pollution beast,ΓÇ¥ and thus ultimately protect the health of the public. One aspect observed was the need to establish a means to measure both ambient air quality and emissions and to develop management processes to develop and implement standards to this purpose. One such aspect was the recognition of the need to somehow quantify or estimate emissions.

The Clean Air Act was enacted in 1963 to protect the quality of the nation’s air resources. It initiated research and development programs to monitor and control pollutants emitted to the atmosphere. Emissions from stationary sources are monitored under the statutes of the act.

The Clean Air Act, with its various amendments through 1990, has produced more and more programs that demand increasing ΓÇ£exactnessΓÇ¥ in quantification of emissions. The basic emission inventory of the 1970-era represented knowingly ΓÇ£grossΓÇ¥ emissions in a jurisdiction in an effort to define the relative impact of facilities, one to another. This provided a basis and rational way to develop program(s) and efforts that would result in reductions in the appropriate groupings of facilities, for the correct pollutants and with an approximate fairness of application of the ΓÇ£painΓÇ¥ and economics of the resulting emission controls. As air quality management has evolved and become more refined, modeling has become extremely important and critical to the precision and ΓÇ£dependabilityΓÇ¥ of the results. The 1990 Amendments brought new levels of ΓÇ£expectationΓÇ¥

for additional uses such as assessment of emission fees, emission trading programs and other such applications.

A young Public Health Service engineer officer named Robert (Bob) Dupree took on the ΓÇ£awesome taskΓÇ¥ of making a broad compilation of emission estimation information and emission factors that could be used by states and by the PHS in the interstate abatement actions and other studies that were a primary focus of the organization. He compiled all such information that he could get his hands on, including the preceding documents, field notes and guesses, quotes of individuals who were experimenting, and other profound and inspired information. Thus, (the First Edition of) ΓÇ£A Compilation of Air Pollutant Emission FactorsΓÇ¥ (better known perhaps as AP-427 ) was published in 1968. This document continues today.

In later years, from the late 70ΓÇÖs and thereafter, many efforts have been made to more precisely assess the errors in emissions from inventories.

There are many variables that can make a difference in the generation and estimation of emissions. Factors such as design, maintenance, temperatures, control device selection and design, fuels, synergistic combinations of minor constituents of fuels, etc. can cause two fold and even 10-fold or more variation in emissions measured. Even measured data are often suspect and subject to errors and concerns regarding validity, so how can emission estimates using average conditions as applied to another facility be any less of concern? The test method and procedures and the manner the data are reported are definitely important to the interpretation and use of the data.

It was impractical (or impossible) to put the same high volume air sampler into a stack and orient it in such a way to provide any meaningful relationship between stack emission measurements and those measured in the ambient air. Thus, the technical community came up with other ways to attempt to quantify the emissions from an emission source or stack. The method that gained acceptance for total particulate with the implication of being compatible with the emission standard, and perhaps ambient data, became known as Method 5.

What Are The Health Impacts Of Air Pollution?

Ozone is a gas composed of molecules with three oxygen atoms. (The oxygen we need for life is made up of molecules with two oxygen atoms). Ozone forms in the lower atmosphere when a combination of other pollutants, usually nitrogen oxides (NOx) and volatile organic compounds (VOCs), ΓÇ£cookΓÇ¥ together in sunlight through a series of chemical reactions. NOx and VOCs are produced primarily when fossil fuels such as gasoline, diesel, oil, natural gas or coal are burned or when solvents and some other chemicals evaporate. NOx is emitted from power plants, motor vehicles and other sources of high-heat combustion. VOCs are emitted from motor vehicles, oil and gas operations, chemical plants, refineries, factories, gas stations, paint and other sources.

Climate change – higher temperatures increasing ozone production. Because the reactions take place in the atmosphere, ozone often shows up downwind of the sources of the original emissions, sometimes many miles from where it formed.

Ozone air pollution is sometimes called ground-level ozone.

Factories, power plants, and diesel- and gasoline-powered motor vehicles (cars and trucks) and equipment either directly emit fine particles or generate the precursors such as nitrogen oxides (NOx) that can form into fine particles in the atmosphere. Other sources include wildfires and burning wood in wood stoves or residential fireplaces.

Many particles are so small as to be invisible, but when pollution levels are high, the air can appear thick and hazy.

Ozone gas is a powerful lung irritant. When it is inhaled into the lungs, it reacts with the delicate lining of the airways, causing inflammation and other damage that can impact multiple body systems. Ozone exposure can also shorten lives.

The damage ozone does to the body can be deadly. Recent research has affirmed earlier findings that short-term exposure to ozone, even at levels below the current standard, likely increases the risk of premature death, particularly for older adults. There is also a growing body of evidence that long-term exposures to ambient ozone may be associated with an increased risk of cardiovascular and respiratory disease mortality.

Researchers estimate that PM2.5 (fine particulates) is responsible for nearly 48,000 premature deaths in the United States every year.

Ozone has a serious effect on the respiratory system, both in the short-term and over the course of years of exposure. When ozone levels are high, many people experience breathing problems such as chest tightness, coughing and shortness of breath, often within hours of exposure. Even healthy young adults may experience respiratory symptoms and decreased lung function.

Other breathing problems that have been tied to short-term exposure to ozone include:

ΓùÅ Worsening of symptoms, increased medication use, and increased emergency department visits and hospital admissions for people with asthma and COPD;

ΓùÅ Susceptibility to respiratory infections such as pneumonia, resulting in an increased likelihood of emergency department visits and hospitalizations.

Living with ozone pollution long-term may cause lasting damage to respiratory health, including:

ΓùÅ Development of new cases of asthma in children;

ΓùÅ Damage to the airways, leading to development of COPD;

ΓùÅ Increased allergic response.

The inflammation and systemic stress caused by short- and long-term exposure to ozone can also do damage to tissues, DNA and proteins throughout the body, which can cause or worsen other disease conditions over time. These include:

ΓùÅ Increased risk of metabolic disorders, including glucose intolerance, hyperglycemia and diabetes;

ΓùÅ Impact on the central nervous system, including brain inflammation, structural changes and possible increased risk of cognitive decline;

ΓùÅ Increased likelihood of reproductive and developmental harm, including reduced fertility, preterm birth, stillbirth and low birth weight;

ΓùÅ Possible cardiovascular effects ΓÇô although according to the most recent EPA review, the evidence linking ozone to heart disease, heart failure and stroke is mixed.

Health Equity: Research has shown that people of color are more likely to be exposed to air pollution and more likely to suffer harm to their health from air pollution than white people.49, 50 Much of this inequity can be traced to the long history of systemic racism in the United States. Discriminatory practices such as redlining, the systematic outlining of riskier neighborhoods by mortgage lenders, institutionalized residential segregation in the 20th century, impairing the ability of many people of color to build wealth and limiting their mobility and political power. Over the years, decision-makers have found it easier to place sources of pollution, such as power plants, industrial facilities, landfills and highways in economically disadvantaged communities of color than in more affluent, whiter neighborhoods. The resulting disproportionate exposure to air pollution has contributed to high rates of emergency department visits for asthma and other diseases.

Children, seniors, underlying health conditions and people living in poverty are also at risk.

From APTI 450 Course Manual

Stack Testing Questions

Where Can I Find a Copy of SW-846?

Hard copy

National Technical Information Service (NTIS)

5285 Port Royal Road, Springfield, VA, 22161

Ph: (703) 487-4650

Fax: (703) 321-8547

E-mail: Info@NTIS.FEDWORLD.GOV

Website: https://www.ntis.gov.

Electronic copy

Could You Please Explain the Difference Between Isokinetic and Anisokinetic Sampling?

Isokinetic sampling conditions exist when the velocity of the particles and gases entering the probe nozzle tip (Vn) is exactly equal to the velocity of the stack gases (Vs), that Vn = Vs. Percentage isokinetic is then calculated:

Percent isokinetic (% I) = Vs/Vn X 100

When Vn does not equal Vs, we have anisokinetic conditions where sample concentrations can be biased because of the inertial effects of particles in the gas stream. The particle composition and sizes in the gas stream affect how much there will be on the final pollutant mass rate (PMR) from the facility. In general, the following conditions exist in a stack gas stream:

- Small particles (< 1 micron) tend to follow the stream lines of the gas stream. If the source is composed of only small particles, then there is little effect on whether you sample above or below isokinetics, thus little effect on the PMR.

- Large particles (> 5 microns) tend to move in their own initial direction. For under isokinetic sampling (the nozzle is bringing in gas at too low a rate), the gas stream ΓÇ£bunches upΓÇ¥ at the nozzle inlet. The large particles tend to ΓÇ£punch throughΓÇ¥ the ΓÇ£stream linesΓÇ¥ (due to their own inertia) and into the nozzle area (they should have gone around the nozzle), thus biasing the PMR and giving results more associated with a lower sample volume. Consequently, there are too many large particles for the small volume sampled. For over isokinetic sampling (the nozzle inlet velocity is greater than the passing gas stream velocity), the nozzle brings in gas not directly in front of it. The large particles, due to their inertia, do not follow the stream lines and continue in the same direction. Thus, the nozzle samples a non-representativeness of large particles in the gas stream, but for twice the volume of gas sampled through the nozzle (the larger particles enter the nozzle as if 100 % isokinetic sampling was occurring). The small particles enter the nozzle outside the effective area of the nozzle (the small particles follow the bent stream lines into the nozzle). Consequently, with the combination of the effects of the large and small particles, the PMR increases.

- Intermediate particles are somewhat deflected for the stream lines of the gas stream.

We use this information in determining if you should reject or accept the stack test if the percent isokinetics are outside the 90-110 % limits and the source PMR were within their limits. If the source test report shows that the percent isokinetics was under 90 % and majority of the particles were < 1 micron in size, then the test should be accepted since fine particles affect PMR very slightly. In the same manner, if the particles are > 5 microns and the percent isokinetics are less than 90 %, then the test should be definitely accepted since the results are bias high due to large particles (more large particles for a smaller sample volume). Therefore, accept the results even if the isokinetics were below 90 %

Now, if the PMR is above the emission limit and we have < 90 % isokinetics, one can multiply the PMR by the factor % I/100 and recalculate the PMR. If this adjusted PMR is still higher than the standard, then the test is accepted even with the percent isokinetic over 110 (the results are in favor of the EPA). On the other hand, if the adjusted PMR is lower than the standard (thus bringing them into compliance), then reject the test and require a retest to be performed.

If the PMR is above the emission limit and the % I is above 110 %, then the test should be accepted because the PMR is equal to the true value or bias low relative to it; thus, the PMR is over the standard. If PMR is below the standard and the % I is above 110 %, then perform the same correction as above to the PMR (multiply by % I/100), and if it is still below the emission limit, the test should be accepted. The PMR meets the standard even though the maximum adjustment (biases due to large particles) has been made. On the other hand, if the adjusted PMR exceeds the standard, you can accept the test results even though they did not meet the 90-110 % I because they still exceed the standard.

(WIP) Where Do I Go to Get References to Title III Hazardous Air Pollutants (HAPs), Their Boiling Points, and Vapor Pressure?

Γ¥ùDuring the presentation on Defining Hazardous Air Pollutants (HAPs), we discussed the methodology EPA uses to define the Clean Air Act Amendments of 1990, Title III, HAPs by boiling point (BP) and vapor pressure (vp). <– Either provide this presentation or reword/remove thisΓ¥ù

The EPA uses eight categories to define HAPs according to vapor pressure:

- Very Volatile Organic Compounds [VVOC] (vp> 380 mm Hg)

- Very Volatile Inorganic Compounds [VVINC] (vp> 380 mm Hg)

- Volatile Organic Compounds [VOC] (vp 0.1 to 380 mm Hg)

- Volatile Inorganics [VINC] (vp 0.1 to 380 mm Hg)

- Semi-volatile Organics [SVOC] (vp 10-1 to 10-7 mm Hg)

- Semi-volatile Inorganics [SVINC] (vp 10-1 to 10-7 mm Hg)

- Non-volatile Organics [NVOC] (vp < 10-7 mm Hg)

- Non-volatile Inorganics [NVINC] (vp < 10-7 mm Hg)

Using boiling points, the EPA defines HAPs by three broad categories:

- Volatiles (VVOC/VVINC/VOC/VINC) BP < 100 C

- Semi-volatiles (SVOC/SVINC) BP 100 to 300 C

- Particles (NVOC/NVINC) BP > 300 C

We use this information to help us pick the proper sampling train to capture our analytes. Particles would use a filtration technique, semi-volatiles would use both filtration and adsorbent, and volatiles would a combination of adsorbents in the sample train.

Γ¥ùYou were provided a copy of the paper written by Larry Johnson and myself that included the listing of the CAAA of 1990 Title III HAPs and appropriate sampling methods from EPAΓÇÖs SW-846 Compendium for each of the listed HAPs. <– The document in question needs to be provided and this section reworded, or removed.Γ¥ù

Regarding the availability of documents that list the BP and vp for the Title III HAPs, the EPA has funded three documents which have as part of them BP and vp for the Title III HAPs. They are:

- Ambient Measurement Methods and Properties of the 189 Clean Air Act Hazardous Air Pollutants (HAPs), EPA-600/R-94/187, October 1994. (EPA Project Officer: Bill McClenny, 919-541-3158).

- Simultaneous Control of PM-10 and Hazardous Air Pollutants II: Rationale For Selection of Hazardous Air Pollutants as Potential Particulate Matter, EPA-452/R-93/013, October 1992 (EPA Project Officer: Gary Blais, 919-541-3223).

- Screening Methods for the Development of Air Toxics Emission Factors, EPA-450/4-91-021, September 1991 (EPA Project Officer: Bill Kuykendal, 919-541-5372).

To obtain copies of these documents, you can order from EPAΓÇÖs National Technical Information Service (NTIS), 5285 Port Royal Road, Springfield, VA, 22161, (703-487-4650, email: Info@NTIS.FEDWORLD.GOV, Internet: https://www.ntis.gov.

Γ¥ùAdditionally, you may call each of the EPA Project Officers and have them send you a copy. You may need to be persistent in your demands for a copy.

In addition, you can find the chemical and physical properties (i.e., vapor pressures and boiling points) for many HAPs online. A useful site is: https://chemfinder.camsoft.com <– Is this still true/recommended? This website doesn’t exist anymore or was changed.Γ¥ù

How Do You Take a Reading For Delta p and Delta h When The Meniscus Line Is Not Horizontal To The Manometer Tube?

When reading a meniscus, the analyst must be very careful that no error is introduced into the reading due to parallax. Under normal conditions, the chemist reads the meniscus on a horizontal ΓÇ£line-of-sightΓÇ¥ at the bottom of the crescent-shaped body from the concave wetting of the liquid on the walls of the container (convex if it does not, i.e. mercury in a glass tube). Remember, the error associated with 0.1 in. water in reading the delta p was 2.4 % associated with the mass emission rate. One can read the incline manometers on the Method 5 sample box to within 0.05 in. water. Therefore, the error would only be very slight to the other possible errors in recording data and the operation of the sample train. This is also true for reading the delta h. When reading the delta h or delta p in the field, keep your ΓÇ£line-of-sightΓÇ¥ horizontal and read the ΓÇ£bottomΓÇ¥ of the crescent-shape of the meniscus.

(WIP) You Mentioned MACT Standards and EPAΓÇÖs Timeline. Can You Further Explain the MACT Bins?

In Lecture 2, Regulations, we discussed EPAΓÇÖs progress associated with the implementation of the MACT standards, which contain sampling and analytical guidance on quantifying emissions covered by the standard. In December, 1997, EPA submitted a report to Congress entitled: Second Report to Congress on the Status of the Hazardous Air Pollutant Program under the Clean Air Act. According to the report, EPA has fulfilled the 2- and 4-year groups (bins) for approximately 25 % of the 173 listed source categories in the Clean Air Act Amendments of 1990. The Agency is, however, falling behind on promulgating standards for the 7- and 10-year groups. Twenty-nine (29) new standards were to be originally due in 1997, but will now be promulgated in 1998. With each of these standards, test methods must be identified for compliance purposes.

One of the interesting areas that is still under discussion is whether residual risk (10 -6) issues will apply once the MACT standard is in place for a source category. As you recall in our presentation, we discussed the the requirements in the CAAA of 1990 that the after applying MACT, the Agency can return to the source category and apply additional controls for residual risk! This issue has not been resolved to date and is one of the reasons the Agency is behind on meeting the MACT schedule identified in the CAAA of 1990. Failure to meet the schedule would require the Agency to set case-by-case MACT standards, which might lead to more stringent application of control technology and emission limits. The Agency would like to prevent a case-by-case MACT program, due to cost and manpower.

Consequently, the Agency has developed a MACT Partnership Program. The program is designed to ease the burden of establishing MACT standards for all source categories and help the Agency meet its schedules for promulgating standards. The program has two phases: Phase I involves the Agency developing a presumptive MACT standard based on limited data it has gathered (without additional stack test). During this phase, EPA and state/local agencies agree on the presumptive standard. Phase II involves final-standard development, which then brings in stakeholders (industry, consultants, affected facilities etc.) for final rule development. The two phase approach reduces the normal time of MACT standard development from 4 years to about 2 years.

(WIP) How Do We Use The Fo Factor in Determining Validity of Orsat/CEM Analysis for O2/CO2?

Γ¥ùNote: I would recommend defining what Fo Factors means in relation to this industry/question

Additionally, the answer references a table that isn’t providedΓ¥ù

Fo factors can be used to evaluate the correctness of the Orsat or CEM system performing analysis for CO2/O2. The following table illustrated the typical range for Fo factors for specific fuel types:

Using the following formula, one can check the accuracy of the Orsat or CEM used to monitor O2 and CO2:

Fo = 20.9- O2/ %CO2

If calculated Fo value does not fall within this range of +/- 10 %, then something is wrong with the reported CO2 and O2 concentrations.

(WIP) Benzoic acid, at high concentrations, has appeared in my field blanks, trip blanks, and samples using SW-846, Method 0010. Is benzoic acid real or a breakdown product of XAD-2 resin?

XAD-2 is a cross-linked styrene-divinylbenzene organic polymer adsorbent. When used for ambient and source testing, the native XAD-2 must be certified clean prior to field application. This requires Soxhlet extraction with an organic solvent ( 10% diethyl ether in hexane or methylene chloride) to remove residual organics (i.e., benzene, toluene or the xylenes) from the surface of the polymer. Consequently, when ready for field use, the XAD-2 should come with a ΓÇ£Certificate of CleanlinessΓÇ¥ from the laboratory indicating that there are no residual organics (i.e, < 4 ug/g of individual organics) on the resin bed. This is very important since the detection limits we are trying to reach are 1.0 ng/m3. Consequently, the benzoic acid should not be a contaminant on freshly extracted XAD-2 resin.

The field and trip blanks should also help one determine what is the source of the benzoic acid. When charging and recovering the Method 0010 sample train, the field blank should be exposed to the same atmosphere as the sample cartridge. This means opening up the field blank and setting it in the same area as where the Method 0010 sample train is being charged or recovered. At the end of each activity, the field blank is capped and stored with the other samples. If benzoic acid is in the atmosphere from fugitive emissions, it would effect both cartridges (sample and field blank) the same. As you recall, the trip blank is never opened. The trip blank is prepared just like a sample, but is never exposed to the atmosphere.

However, because of itΓÇÖs chemical structure, XAD-2 can degrade when exposed to heat, sunlight, and oxidants. To minimize the influence of heat, Method 0010 requires that the source gas entering the resin bed be maintained to < 68 F through the use of a coiled condenser during sampling to prevent deterioration of the XAD-2 resin. In addition, after sampling, Method 0010 requires that the resin bed be maintained at < 4 C until extraction to provide continue integrity of the resin and analytes on the resin.

To minimize the influence of ultraviolet light from breaking down the resin, we suggest that the resin cartridge always be wrapped in hexane-rinsed aluminum foil. This protects the resin from harmful ultraviolet light, once again maintaining integrity of the resin. The aluminum foil also minimizes contamination from hands on the resin cartridge.

The influence of oxidants has only recently come to light. During sampling, we are pulling large volumes of stack gas containing many oxidants (i.e., oxygen, ozone, peroxides etc) through the resin bed. It has been speculated that, during sampling, benzoic acid is produced as an artifact from the oxidation in the stack gases. Polymers like XAD-2, because of their substituted benzene ring structure, slowly degrade and give off compounds like toluene, styrene, and similar compounds that oxidize to yield the benzoic acid during sampling.

Γ¥ùFor more information associated with semi-volatile monitoring and background concentrations of the XAD-2 resin, please contact Tom Ward, US Environmental Protection Agency, MD-74B, Research Triangle Park, North Carolina 27711 (919-541-3788). <– Still true?Γ¥ù

(WIP) What Is The Difference Between Method 9 and SIP Series VE (Methods 203 A, B, and C)? What Is The Difference Between Federal Reference Method 29 and SW-846 Multi-metal Method?

In terms of regulations, EPA has developed a series of methods which address different programs. The sources of the different test methods are as follows:

- 40CFR 60, App. B: 00 Series, Performance Specification Test

- 40CFR 51, App. M: 200 Series, SIP Methods

- 40CFR 60, App. A: 00 Series, Federal Reference Methods

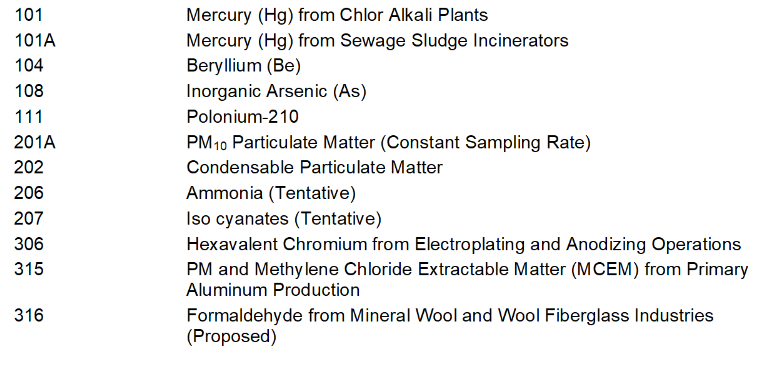

- 40CFR 61, App. B: 100 Series, NESHAP Methods

- 40CFR 63, App. A: 300 Series, MACT Methods

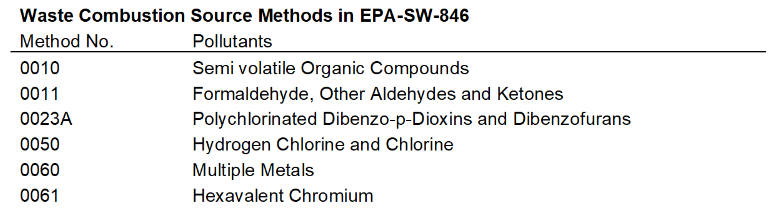

- 40CFR264/265: 0000 Series, SW-846 Hazardous Waste Incinerator Methods

The EPA has promulgated different test methods to address different regulatory standards. Some of these methods are the same method, but identified differently depending upon the regulatory program.

Consequently, there is no difference between FRM 29 and SW-846, Method 0060 for multi-metal sampling and analysis from industrial and hazardous waste incinerators. For more information associated with FRM 29, contact Mr. Bill Grimley, US EPA, EMC, MD-19, Research Triangle Park, NC, 27711, (919) 541-1065.

Methods 203A, B, and C are field test methods, as found in 40 CFR 51, Appendix M (Test Methods for State Implementation Plans), applying Federal Reference Method 9 (40 CFR 60, Appendix A) procedures for state agency inspectors and visible emissions observers to use in determining visible emission compliance with averaging times other than 6 minutes, time exception standards, and instantaneous emission standards. The methods also address visible emission sources other than the traditional stack emission point including sources of fugitive emissions. Γ¥ùFor more information concerning EPA Methods 203 A, B, and C, please contact Mr. Peter Weslin, US EPA, Emission Measurement Center, MD-19, Research Triangle Park, NC, (919) 541-5242. <– Is this still true?Γ¥ù

If A Velocity Profile Has Been Performed on a Two-Set of Ports, One Port Above The Other, Can The NESHAP Test Be Performed At the Lower Port?

(Example: Lower Port 1.5 Diameters Downstream, Upper Port 2 Diameters Upstream)

Alternative test method approval or variation to a Federal Reference Method (FRM) has always been on a ΓÇ£case-by-caseΓÇ¥ basis. At the discretion of the Administrator, the following allowable alternatives can be made:

- Approve minor changes to the reference test methods;

- Approve an equivalent method;

- Approve an alternative method which has been demonstrated adequate for determining compliance at a specific source; and

- Waive the requirements for performance testing.

The Administrator is a Regional EPA official or officials of other agencies, such as regional, state, and local personnel.

In general, for an alternative method to be accepted, it must:

- Be applicable and properly executed;

- Include a detailed, written description of option in test report; and

- Provide supporting data and rationale to show validity of option in the specified application.

In considering an alternative to a Federal Reference Method, Agency criteria for evaluating minor modifications should determine that:

- Effect (or changes to the methodology) will be insignificant on final emission data results;

- Changes will accommodate a situation that is considered unique and would apply only to sample site for which it is allowed;

- All allowable alternative procedures in reference method will provide emission results of equal or greater value than standard procedures (Bias Concept); and

- Agency can use same bias concept technique when evaluating alternative methods.

With reference to the question, the source would have to provide the needed information to show that the two sampling ports are equivalent and that a negative bias does not exist at the lower port. In essence, the source should complete the Alternative Method Approval Request, found at the back of your Student Workbook. This form contains four major sections: 1. Requesting Organization

2. Specific Application of the Alternative Method

3. Description of the Alternative Method

4. Support Data

As part of this request, the source would provide data (to support the selection of the lower port) showing that cyclonic flow does not exist at the lower port, both velocity profiles are representative of the source emissions and do not vary within 10 % of each other, and if a gas test method is being performed, the concentration profiles for O2 (or CO2) are within 10 % of each other as determined by a portable O2/CO2 continuous emission monitoring (CEM) system.

The source would provide this support data as Part 4 of the Alternative Method Approval Request.

(WIP) Has FTIR Been Used in Stack Testing?

FTIR (Fourier-transform infrared) has been used as both emission and process monitoring at primary/secondary aluminum facilities, secondary lead, asphalt roofing, Portland cement plants, and wool fiberglass/mineral wool facilities and utilities. FTIR use has been validated for the determination of over 37 hazardous air pollutants (HAPs) directly, with an additional 18 HAPs through sample concentration. EPA presently maintains a spectra library on the Internet.

FTIR is presently being used to quantitate emissions from a variety of sources. Under 40 CFR Part 63, Appendix A, FTIR is being proposed (tentative: under consideration) for three methods. They are:

- Method 318: Formaldehyde, Phenol, and Methanol Determination by FTIR;

- Method 320: Generic Extractive FTIR Method for Industrial Emissions; and

- Method 321: FTIR For HCl From Portland Cement Kilns.

Method 318 test method using FTIR is industry specific for the mineral wool industry, while Method 321 is industry specific for the Portland cement industry. Method 320 is a generic, self-validating FTIR test method that can be applied to any source category. It has the option for using in screening, validation requirements (Method 301), and self-validation requirements (spiking etc.). Method 321 will be a compliance method using FTIR for HCl emissions from Portland cement plants as part of the MACT regulations. The system uses a heated sample line and a filter maintained at 350 F to control ammonium chloride formation. Method 318 will more than likely be promulgated in the fall of 1998, while Methods 320 and 321 will be promulgated in the spring of 1999.

Γ¥ùFor additional information associated with the application of FTIR to monitoring industrial emissions, please contact Ms. Rima Dishakjian, U.S. Environmental Protection Agency, MD-77A, Research Triangle Park, NC, 17711, (919) 541-0443.

Finally, EPA has produced a video entitled: FTIR for Emission Measurements. Please contact Ms. Dishakjian for receiving a copy. <– Is this still true?Γ¥ù

(WIP) How do I sample for chloroprene?

Chloroprene (C4H5Cl), 2-chloro-1,3-butadiene, has a vapor pressure of 226 mm Hg @ 25 C, a boiling point of 59 C, and a molecular weight of 88.5 g/g-mole. As such, it is classified as a volatile organic compound (VOC).

Being a VOC, one would think that SW-846, Method 0030 would be the ideal choice for capturing chloroprene from stack gases. Indeed, Method 0030 is applicable to those organic compounds with boiling points from 30-100 C, of which chloroprene certainly is a member. However, we have identified chloroprene as questionable using Method 0030. The EPA has data that shows Method 0030 works well in the laboratory under control conditions for capturing chloroprene, but mixed results in the field. It might be that chloroprene breaks through (low breakthrough volume) the Tenax and Tenax/charcoal traps in the Method 0030 sampling train or that oxidants in the stack gas reacts with the captured chloroprene on the resin bed, thus providing a negative bias to our concentration. We really donΓÇÖt know, but can only speculate.

However, the EPA does have data to show that Method 0031 gives good results based upon a Method 301 validation. Method 0031 uses three adsorbent traps (Tenax, Tenax and Anasorb-747). Anasorb-747 is a carbon molecular sieve adsorbent, with large surface area and very amenable to capturing volatile organics. Also remember that Method 0031 allows the sampling rate to be as low as 0.25 L/min, thus allowing considerable more contact time for the organic with the sorbent resins!

Consequently, the method of choice for quantitating chloroprene from industrial sources is SW-846, Method 0031.

The EPA, Emission Measurement Center, Research Triangle Park, NC has posted on their web site relevant methods and procedures for emission testing and monitoring. The website is designed to provide the user guide in the application of stack test methods to specific analytes of interest. The methods are presented under five (5) different categories. The categories are based on a combination of (1) the legal status of the methods with regard to their application under federally enforceable regulations and (2) the validation information available on the method and the AgencyΓÇÖs corresponding confidence in application of the method for its intended use.

Category A: Methods proposed or Promulgated in the FR

These methods are used for compliance purposes under 40CFR 60, 61, and 63 by industrial sources. These methods are being reviewed to meet EPAΓÇÖs new format as recommended by the Environmental Monitoring Management Council (EMMC).

Category B: Source Category Approved Alternative Methods

These methods are approved alternatives to the test methods outlined in 40 CFR 60, 61, and 63. They have been used by sources for determining compliance. The Administrator has issued an official EPA letter stating the validity of the methodology as an alternative to the FRMs

Category C: Conditional Methods

These methods have been evaluated by the Agency and may be applicable to one or more source categories. EPA has reviewed the method QA/QC, applicability to a source category, field and laboratory validation studies etc.

This method may be used by State and local programs in conjunction with Federally enforceable programs (e.g., SIP, Acid Rain, Title V Permits etc.). The source must get approval as alternative before using to meet Federal requirements.

Category D: Preliminary Methods

The performance of these methods is not as well defined as those in the conditional category. May be used in limited application as ΓÇ£gap fillingΓÇ¥ methods.

Category E: ΓÇ£Idea BoxΓÇ¥

Methods concepts to promote information exchange.

Γ¥ùWithin each category, the EPA provides examples of test methods for specific analytes. For more information dealing with the application of source methods to specific analytes, contact Mr. Tom Logan, US Environmental Protection Agency, MD-19, Research Triangle Park, North Carolina, 27711, 919541-2580.

For other applications of SW-846 methods in quantifying your target compounds, please contact Ms. Robin Segall, U.S. Environmental Protection Agency, MD-19, Research Triangle Park, North Carolina, 27711, 919-541-0893. <– Still true?Γ¥ù

(WIP) What Are Some Of The Test Methods Available For Monitoring Sulfur Compounds?

Within 40 CFR 60, Appendix A, there are several Federal Reference Methods (FRMs) which are used to monitor both the oxides of sulfur and reduce sulfur compounds. Federal Reference Methods 6 and 8 deal with the oxides of sulfur. Federal Reference Methods 15, 15A, 16, 16A, and 16B deal with the reduced states of sulfur and total reduced sulfur (TRS) compounds.

New techniques have developed over the last several years in monitoring reduce sulfur compounds. Field and laboratory tests have demonstrated the applicability of specially-treated interior whole-air canisters as a sampling mechanism for reduce sulfur compounds. In this application, a gas sample is extracted from the source through a heated sample probe directly into a heated specially-treated interior whole-air canister. After extraction, the canister (still heated) is immediately taken to an on-site laboratory for analysis using gas chromatography coupled to a flame photometry detector or a mass spectrometer. The National Council for Air and Stream Improvement (NCASI) has validated this method (using Method 301) for many organic HAPs, and some reduce sulfur compounds from Kraft recovery boilers.

Other techniques include extractive FTIR, portable gas filter correlation (GFC) systems, ion mobility, specific gas permeation cells and a variety of continuous emission monitoring systems (CEMs). Other techniques for monitoring reduce sulfur compounds from industrial sources can be found in a variety of databases.

There are many different databases available for assisting the analyst in determining which sampling and analytical procedure to use for a particular analyte. Most of the databases are multi-media, containing information involving both water, soil, hazardous waste and air. Some of the more useful databases are:

- Γ¥ùLewis Publishing Company, Compilation of EPAΓÇÖs Sampling and Analysis Methods Database. This database contains 650 method and analyte summaries. Each summary includes method name and EPA number, analyte, CAS registry number, instrumentation, method detection limits, sampling and sample container requirements, and more.

- U.S. Environmental Protection Agency, EPA Environmental Monitoring Methods Index (EMMI) Database, National Technical Information Service (NTIS), 5285 Port Royal Road, Springfield, VA, 22161, (703) 487-4650, E-mail: Info@NTIS.FEDWORLD.GOV, Internet: https://www.ntis.gov. The EMMI database is an automated inventory of information on environmental significant analytes monitored by the EPA and methods for their analysis. The EMMI System serves for enhancement and national distribution to Regional EPA laboratories and offices as the single authoritative source for cataloguing the AgencyΓÇÖs analytical methods. The EMMI database includes information on more than 2,600 analytes from over 80 regulatory and nonregulatory lists and more than 900 analytical methods.

- U.S. Environmental Protection Agency, Air Methods Database, Office of Emergency and Remedial Response, Edison, NJ, (908) 321-6738. The Air Methods Database is a PC-based software package which allows the user to access summarized standard methods for chemical sampling and analysis associated with air emissions. These summaries are used by the user as tools for applicability of a method for an analyte, method detection limits, operating range, and interferenceΓÇÖs of the method and the type of media and sampler used top collect the analyte.Γ¥ù <– Still true?

Additionally, NTIS publishes a pamphlet entitled ΓÇ£Environmental Software and DatafilesΓÇ¥ annually. These pamphlets contain additional sources of current sampling and analytical methods and simulation models, software and datafiles containing test results and chemical properties, and statistical methods.

(WIP) What do I watch for during the resin recovery involved in SW-846, Method 0010?

During the resin recoveries involved with both Method 0010 (Semi-VOST) and Method 0030 (VOST), observe how the resin beds are handled and stored. Are they wrapped in hexane-rinsed aluminum foil to minimize outside influences of ultraviolet light, heat and external contamination? Does each cartridge have a ΓÇ£Certificate of CleanlinessΓÇ¥ associated with itΓÇÖs paperwork? Is each cartridge inscribed with a unique number/letter to identify that cartridge to that specific test run? Is the field blank cartridge exposed to the same atmosphere as the sample cartridge during charging and recovering of the sample train?

During your review, make sure the cartridges are properly capped when not in use and that they are stored at < 4C at all times after sampling. Confirm that the Chain-of-Custody (COC) is properly filled out and the cartridges are properly identified on the COC. Check to see when the cartridges were cleaned (should be on the ΓÇ£Certificate of CleanlinessΓÇ¥ sheet and if the sampling date is within 30 days of that date (Both Method 0010 and 0030 require that the clean cartridges must be used within 30 days from cleaning). Finally, if the cartridge is being used for dioxin/furan sampling (Method 0023A), then insure that proper field surrogates have been applied to the certified clean cartridge prior to sampling (remember, Methods 0010 and 0030 do not require field surrogates to be added to the sample cartridge).

Γ¥ùFor additional information concerning sorbent recoveries, please contact Mr. Gary McAlister, U.S. Environmental Protection Agency, MD-19, Research Triangle Park, North Carolina 27711 (919-541-1062).Γ¥ù <– Still true?

How important is the use of aluminum foil in the protection of the resin beds in SW-846, Method 0010 and 0030?

Aluminum foil serves three purposes to minimize biases associated with Methods 0010 and 0030. First, the hexane-rinsed aluminum foil prevents ultraviolet light from effecting the resin bed and analytes attached to the resin bed. Second, the aluminum foil helps to minimize the influence of heat from either the sun or the stack. In addition, the application of the aluminum foil helps to minimize influence of outside contamination on the walls of the cartridge.

Sometimes in stack testing, it is the small things that can add up to create large biases in the test data. The aluminum foil helps us to maintain some small biases within our accepted control limits.

(WIP )Why is it necessary to purge the filter in the HCl/Cl2 train and why do a leak check in two sections?

SW-846, Method 0050 was designed to sample HCl/Cl2 from hazardous waste incinerators and municipal waste combustors, especially suited for those sources with wet scrubbers emitting acid particulate matter (e.g., HCl dissolved in water droplets). As such, Method 0050 requires isokinetic sampling to insure a representative sample is extracted from the stack. The water droplets containing the dissolved HCl would be extracted in a representative manner from the passing stack gas around the nozzle. However, after the droplets enter the gas sampling train, they may fall out in the optional cyclone or be retained on the heated filter. To address this bias, the method calls for purging the sample train for 30 minutes (purge air through an Ascarite tube) to vaporize the liquid and purge any HCl in the cyclone or retained on the filter and pull it through the train and into the first three impingers. Tests by the EPA have demonstrated that if visible moisture is still in the cyclone or on the filter, then increasing the probe/filter assembly to 177 C with additional purging of 15 minutes will insure complete removal of the HCl from the cyclone/filter to the impinger system.

The two tier leak check procedure identified in Method 0051 (remember, Method 0050 requires a standard FRM 5 full train leak check) requires a leak check of the probe and three-way stopcock, then a leak check from the first impinger through the rest of the sample train. The two tier leak check would allow the stack tester to leak check the probe and three-way valve only one time. The probe/valve assembly would stay in the stack until the end of the testing day. This would allow the tester to run several test, exchanging out the impingers several times and leak checking the impinger/meter box only without removing the probe/three-way valve from the port. This saves some time when multiple runs/tests are being performed at the source.

Indeed, a single whole train leak check can be done each time, which is stricter than what Method 0051 requires.

Γ¥ùFor more information associated with FRM 26, please contact Mr. Terry Harrison, U.S. Environmental Protection Agency, MD-19, Research Triangle Park, North Carolina 27711 (919-541-5233). <– Still true?Γ¥ù

What are the differences between the different ΓÇ£blanksΓÇ¥ used in Stack Testing – Lab, Field, Reagent, and Trip?

There are several different ΓÇ£blanksΓÇ¥ associated with stack testing methodology. They are field, trip, reagent and laboratory blanks. The objective of determining concentration of analytes in the different blanks is to verify the presence or absence of analytes, either those of concern [consequently, those on the target compound list (TCL)] or those analytes which might effect the results through positive or negative biases.

- The trip blank is designed to identify levels of contamination from the exposure of the reagent or sorbent bed to the same atmospheres exposed to the analyte reagent or sorbent bed. The trip blank is prepared in the laboratory with the other reagents or adsorbents prior to shipping to the field. However, the trip blank is never exposed to the field atmospheres. It is simply sent along with the field samples to and from the site. The trip blank identified areas of exposure such as shipping temperatures and pressures, laboratory preparation of field samples and laboratory preparation of field samples for analysis.

- The field blank is similar to the trip blank in that it is also prepared during the preparation of the field reagents or adsorbents. However, the field blank is exposed to the same atmospheres in the field as the field samples. This means that the field blank is opened during the charging of impingers or sorbents in the sample train. The field blank is also exposed during the exchanging of cartridges in SW-846, Method 0030 or when field reagents are being exchanged during a test run. In summary, field blanks consist of additional sample collection media (e.g., sorbent tubes, reagents, filters) which are transported to the monitoring site, exposed briefly at the site when the samples are exposed (but no stack gas is actually pulled through these blanks), and transported back to the laboratory for analysis, similar to a field sample. At least one field blank should be collected and analyzed for each test series.

- The laboratory blank is a sample of the reagents or sorbents used during the sample train reagent preparation or recovery. The laboratory blank is a sample of the extraction solvent, the rinses used during sample recovery, or a sample from the batch of sorbent used to preparing sampling cartridges. Laboratory blanks include both method blanks and instrument blanks. method blanks are carried through all steps of the measurement process (from extraction through analysis). A method blank is typically analyzed with each sample batch. Instrument blanks are used to demonstrate that an instrument system is free of contamination. Instrument blanks are typically analyzed prior to sample analysis and following the analysis of highly contaminated samples.

- The reagent blank is a sample of the solvents used during recovery of the sample train after the test is completed. Reagent blanks for both multi-metal and chromium +6 require that the reagent blank be the same volume as the renses used to recover the samples, from probe to impinger. This is because the blank value is substracted from the sample to obtain a final concentration.

How does Method 0050 differ from FRM 26 or 26A for HCl?

SW-846, Method 0050 is an isokinetic sampling train for the determination of HCl/Cl2 from hazardous waste incinerators and municipal waste combustors, especially suited for those sources with wet scrubbers emissions of acid particulate matter (e.g., HCl dissolved in water droplets. Method 0051 was designed for those stacks which were relatively dry, particulate free. You must use Method 0050 at sources controlled by wet scrubbers that emit acid particulate matter and have water droplets.

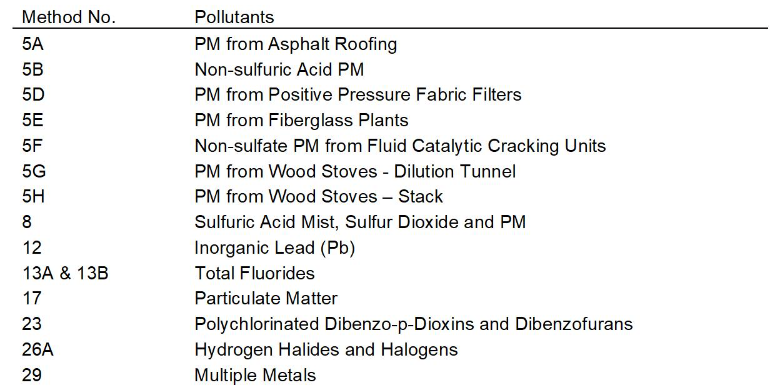

Federal Reference Method (FRM) 26 is the same as SW-846, Method 0051 except FRM 26 is for hydrogen chloride (HCl) emissions only (whereas Method 0051 can quantitate Cl2 also). Finally, FRM 26A is different from SW-846, Method 0050 (both isokinetic), in that FRM 26A is applicable for determining emissions of hydrogen halides (HX) [specifically HCl, HBr, and HF], and halogens (X2) [specifically Cl2 and Br2]. Method 0050 only quantitates HCl and Cl2.

We see a lot of field blank contamination. The stack test companies usually explain this a ΓÇ£laboratory artifactsΓÇ¥ or ΓÇ£false positives.ΓÇ¥ How much ΓÇ£blank contaminationΓÇ¥ should be accepted?

There is no general rule as for a acceptable blank contamination. Of course, you do not want to have your target analytes as part of the ΓÇ£blank contaminationΓÇ¥ above the method detection limits (MDLs).

As specified in the individual methods, the following ΓÇ£blank contaminationΓÇ¥ levels are required to be met before the sorbent is allowed to be used in the sample train:

- Method 0010 (Semi-volatile): 4 mg/kg of total chromatographable organics (TCO);

- Method 0030 (Volatile): 2 ng/1.6 g of target specific analyte;

- Method 0050 (HCl/Cl2): Reagent blank less than 10 % of the sample values; and

- Method 0060 (Multi-metals): Reagent blank less than 2 ug/L of each target metals.

Is the Ascarite purge in Method 0050 required for all runs?

The objective of the Ascarite purge in Method 0050 is to move any entrained HCl/Cl2 on the heated filter or in the optional glass cyclone back to the impingers. This is accomplished by attaching an Ascarite scrubber to the inlet of the probe, with the filter heated to 248 F, purging the train for up to 45 minutes at a desired flowrate of 1 inch of water as indicated by the delta H manometer. The EPA has found that if visible water is observed in the optional cyclone, one can increase the temperature of the filter box to 177 C to help vaporize the water, consequently moving the entrained HCl/Cl2 to the impingers.

In Method 0050, why use sulfuric acid to trap HCl (and how does it work)? Why not use a base solution?

As specified in Method 0050, two impinger reagents are used to separate and trap HCl and Cl2 from the gas stream. Acidic and alkaline absorbing solutions collect gaseous HCl and Cl2, respectively. In the acidified water absorbing solution (i.e., 0.1 N H2SO4), the HCl gas is soluble and forms chloride ions by the following equation:

HCl + H2O = H3O+ + Cl-

The Cl2 gas present in the emissions has a very low solubility in acidified water and

passes through to the alkaline absorbing solution where it undergoes hydrolysis to form a proton (H+), Cl-, and hypochlorous acid (HClO) by the following reaction:

H2O + Cl2 = H+ + Cl- + HClO

Sodium thiosulfate solution is added to the contents of the recovered alkaline absorbing solution ( e.g., 0.1 N NaOH) to stabilize the ClO- and removes the possibility of partial reduction of ClO- to Cl- and the resulting high bias to the results.

The resulting Cl- ions in the separate solutions are measured by ion chromatography by SW-846, Method 9057. Those Cl- ions found in the acidified impingers are related to the HCl emissions and those in the alkaline impingers are related to the CL2 emissions. Thus, through the selection of absorbing solutions and solubilities, we are able to differentiate between HCl and Cl2.

To use only a base wouldnΓÇÖt allow us the ability to speciate and we would also have to change our analytical finish because of the many possible reactions in the base impinger with absorbing HCl along with Cl2.

(WIP) Is the addition of a pH color indicator (~ pH 9 or 8) in the last NaOH impinger allowed in Method 0050/0051?

Jerry Winberry: I have checked with EPAΓÇÖs Emission Measurement Center (EMC) involving the addition of a pH indicator to the last NaOH impinger to show the visual change in color if the normality of the NaOH changes below 0.1 N (pH ~ 10). The EPA has not received a request for approval of the methodology by adding a color indicator to the impinger.

However, thymolphthalein is blue at a pH of > 11, but becomes colorless at a pH < 10. I would see nothing wrong with adding a few drops of thymolphthalein in the last impinger as an indicator of pH change during sampling rather than stopping the test and having to leak check before checking the pH of the last impinger. Do not forget you must receive prior approval from the Administrator before implementation.

Additionally, donΓÇÖt forget our other options to maintaining proper strengths of our absorbing solutions:

- Use stronger base (e.g., 0.5 N NaOH);

- Add additional volume to the last impinger ( e.g., 200 mL); and

- Recharge impinger during sampling.

Why is FRM Method 18 not recommended for HAP testing? Where could FRM Method 18 be used?

Federal Reference Method 18 was promulgated in the Federal Register, 48 FR 48344, October 10, 1983. Since that time, the method has undergone corrections and updates. On April 22, 1994, the method underwent an update for improving the quality assurance/quality control (QA/QC) sections of FRM 18.

When originally promulgated, the method was intended to be used as both a survey method to gain information as to what organics were being emitted from industrial sources and as input to agency models for regulatory activities. FRM 18 is very similar to SW-846, Method 0040, Sampling of Principal Organic Hazardous Constituents from Combustion Sources Using Tedlar Bags. Both methods are sample collection methods, with references to other FRM or SW-846 analytical methods for the analysis of the specific target compound list. However, FRM 18 goes into great detail on how to analyze the survey Tedlar bag on-site by using various techniques for calibrating the gas chromatography system.

As identified in Section 2.1 of FRM 18, the ΓÇ£range of this method is from about 1 part per million (ppm) to the upper limit governed by GC detector saturation or column overloading. The upper limit can be extended by diluting the gases with an inert gas or by using smaller gas sampling loops.ΓÇ¥ Consequently, FRM 18 is truly applicable to those sources with emissions of gaseous organic compounds in the ppm range. Since the method allows for ΓÇ£dilutionΓÇ¥ of the stack gas with inert gas using a Tedlar bag technique, the method is not sensitive to low ppb levels of organics. As you recall in SW-846, Method 0030, we used a Tenax, Tenax/charcoal tubes to capture the hazardous organic constituents from the stack gas. After collection, we performed a ΓÇ£thermal desorptionΓÇ¥ on the tubes to reach the desired detection limits needed for risk base calculations. Those detection limits were in the 1 ppb range. Whereas, SW-846, Method 0040 is in the 100s ppb range and FRM 18 in the 1 ppm range.

What stack test method is used to sample diallyl phthalate (DAP)?

Jerry Winberry: Diallyl phthalate (DAP) is a nearly colorless liquid, and is insoluble or has limited solubility in gasoline. It is soluble in most organic liquids, however. It is also a primary plasticizer for most resins, and is a polymerizable monomer which will polymerize with heat and catalyst into a clear, hard, insoluble polymer.

Diallyl phthalate has a boiling point of 158-165 C ( 4 mm) and a vapor pressure of 1.5 mm at 150 C. Diallyl phthalate is therefore defined as a ΓÇ£semi-volatile.ΓÇ¥

SW-846, Method 0010 would be the best selection for a method to extract and quantitate diallyl phthalate from a source. Since diallyl phthalate is not a traditional semi-volatile using Method 0010, I would suggest, as does the method, performing several laboratory evaluations of spiking known concentrations of DAP on clean, certified XAD-2 cartridges.

First set of experiments would to evaluate the extraction efficiency of XAD-2 releasing the DAP to the extraction solvent. This experiment would require spiking three (3) XAD-2 cartridges with neat DAP (spiking in the center of the XAD-2 resin bed) at concentrations expected from the source. You would then perform a normal Soxhlet extraction to determine the system efficiency (remember, the XAD-2 resin bed must also be spiked with the normal laboratory surrogates). The recovery of the DAP from the XAD-2 cartridges must fall within Method 0010 surrogate recovery limits of 50-150 %.

The second set of experiments would involve spiking three (3) cartridges with the same level of DAP as used in the extraction experiment. This time, the XAD-2 is challenged with clean, ambient air for the same sampling period as Method 0010 sampling time would require. The XAD-2 cartridges would be recovered in the same manner, soxhlet extracted and analyzed by GC/MS. Once again, the recovery limits would be 50-150 %.

During this experiment, you are determining whether the DAP will remain on the XAD-2 resin bed during sampling and whether there is any possibility of degradation of the DAP during sampling.

On the ambient side, we have excellent recoveries of DAP using combination of polyurethane foam (PUF)/ XAD-2 cartridges for trapping phthalates from ambient air. Our laboratory experiments show an average of 92 % recovery for most of the phthalates. Based upon that experience, I feel that SW-846, Method 0010 will be adequate for DAP.

(However, the phthalates can be a background problem for XAD-2 resin. I would therefore suggest that you clean, certify the resin to show that you do not have phthalates as background concentration on the resin, but use the resin only once. Use clean resin each time to minimize possible problems.)

If the KOH recirculation pump fails for a period of time (i.e., 20 minutes), must the test be invalidated for Method 0061?

Shouldn’t the FRM 201A isokinetic be between 80-120 % rather than 60-140%?

FRM 201A does state in Section 6.3.5 that the allowable acceptable limits for isokinetics is between 80-120 % or that no sampling point be outside the delta p min or delta p max during sampling.

FRM 201A is sampling at a constant rate through a PM-10 cyclone. The objective of FRM 201A is to maintain the correct flow through the nozzle, consequently the PM-10 cyclone, to maintain the proper cut-side of the cyclone (9-11 microns) during sampling. By not sampling isokinetically, as in Method 201, we are ignoring the larger particles. Our assumption is that our bias will be small because we are only interested in the small particles (< 10 microns) which will follow the gas stream and enter our nozzle if we select a constant sampling rate that is close to 100 % isokinetics based upon the geometry of the cyclone and nozzle selection. Maintaining the proper cut-size of the cyclone is the most important aspect of this method, not the % isokinetic limit.

Jerry Winberry: Consequently, if I was reviewing a FRM 201A test report and they showed that the cyclone cut-size was maintained with the 9-11 micron size range, but isokinetics were 75 %, I would accept the test knowing that I am only interested in small particles (< 10 micron). Remember, under isokinetics biases the mass emission high or in favor of the regulatory agency!

On Method 0061, can both chromium and Cr+6 be measured in the same test? If someone wanted only total chromium, wouldnΓÇÖt it be better to run the multi-metal train (Method 0060)?

SW-846, Method 0061, Determination of Hexavalent Chromium Emissions From Stationary Sources, is applicable for the determination of Cr+6 from hazardous waste incinerators, municipal waste incinerators, and sewage sludge incinerators. With the approval of the Administrator, this method may also be used to measure total chromium.

For total chromium, you would operate the Method 0061 sampling train in the same manner for Cr+6, but would rinse all active components of the sample train (from probe inlet to the fourth impinger) with 0.1 M HNO3 for total chromium. Remember, one filters the insolubles from the 0.1 N KOH recovered solutions and analyze the insolubles for total chromium also (along with the 0.1 M HNO3 rinses). Consequently, the total chromium number would be the Cr+6 number plus the insoluble total Cr number plug the 0.1M HNO3 total Cr rinse.

For total chromium only, it would be easier to operate the multi-metals train (SW-846, Method 0060, without the KMNO4 impingers for Hg) rather than the Cr+6 train because of the special adaptor for the probe assembly and recirculating first impinger.

Is stack velocity ΓÇ£directlyΓÇ¥ proportional to the absolute temperature, since PV=nRT?

Stack velocity is NOT directly proportional to absolute temperature. The Ideal Gas Equation is PV=nRT, where ΓÇ£VΓÇ¥ is volume of a gas in relationship to the temperature, ΓÇ£TΓÇ¥ of the gas.

Velocity of a gas stream is determined by the following equation:

V = KpCp [(Ts)(delta p)/(Ps)(Ms)]1/2

Now, Qs = (As)(vs) where As is the area of the stack and vs is the velocity of the stack gas.

The pmr (pollutant mass rate) = (cs)(Qs) where cs is the concentration of the pollutant (mass per unit volume) and Qs is the volumetric flow rate of the stack gas [(As)(vs)].

(WIP) Would you consider FTIR as an approved EPA method? What is the reference to the EPA protocol?

Γ¥ùThis entire section references works that are not linked, they either need to be provided or this entire answer needs to be redoneΓ¥ù

Indeed, FTIR is a ΓÇ£mainstream ΓÇ£ method for the EPA. In support of the MACT regulations, the EPA has promulgated and proposed several FTIR methods to help states determine whether sources are meeting their emission limits. Under 40 CFR Part 63, Appendix A, the various FTIR methods applicable to state to use in their SIP programs as part of the MACT program are discussed. The 300 series found in 40CFR63 include the following FTIR methods:

- Method 320- FTIR Extractive Technique Applicable to Emission Sources (Proposed March 24, 1998);

- Method 321- FTIR For HCl Emissions (Proposed March 24, 1998);

- Method 318- FTIR For Phenols, CO, COS, and Methanol (Proposed March 31, 1997);

- Performance Specification Test (PST) 15- FTIR CEMS (Promulgated, Fall, 1998).

Additionally, as part of The Compendium of Methods for Sampling and Analysis of Organic Compounds in Ambient Air-Second Edition, there is the Compendium Method TO-16 dedicated for the application of FTIR technology for monitoring organic emissions in the ambient air. If you would like a copy of this method, Γ¥ùplease contact Jerry Winberry. He is the principle author of the Organic Compendium.

For more information about the applicability of FTIR to source emissions, contact Rima Dishskjian of EPAΓÇÖs EMC at RTP (919-541-0443).Γ¥ù

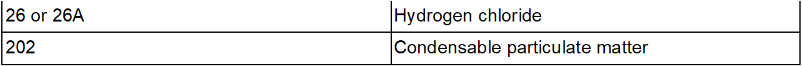

Intro to Isokinetic Sampling

This video briefly covers:

1. Intro to Isokinetic Sampling

2. Our contribution to the industry

3. What we can do for you

Intro to EPA Method 2 and Flow Measurement

In this video we cover:

1. Brief introduction to US EPA Method 2

2. The challenges problems involved in performing method 2.

3. Our available systems for Method 2, 2F, and 2G.*

*Apex Instruments is constantly striving to create better products and improve existing ones. For the most up-to-date information on our available products, please visit our website.

If you have any questions, please contact an Apex Instruments Sales Representative.

Sales@apexinst.com

What is Method 4?

EPA Method 4 is used to determine the moisture content of stack gases. A gas sample is extracted at a constant rate from the source. Moisture is then removed from the sample stream and the condensate is measured either by volume or by mass. While Method 4 can be run independently, it is often conducted with a pollutant emission measurement run, such as Method 5.

For more information and documents about Method 4, please consult the EPA’s Method 4 webpage.

Apex Instruments offers a Method 4 Sampling Kit. If interested in Method 4 sampling, Apex Instruments works with our customers to make sure we are providing the correct products for your project and will provide you with a price quote. For any questions about our sampling kit, please contact sales@apexinst.com.

Equipment Needed for Method 4:

ΓùÅ Probe

Γùï M5 style

Γùï Stainless steel tubing

ΓùÅ Gas extracting pump

Γùï Console

Γùï Tedlar bag pump

ΓùÅ Sample line

Γùï M5 or M4 style, or Teflon tubing

ΓùÅ Impingers

Γùï M5 or M4 style impinger train setup

ΓùÅ Pre-filter optional

ΓùÅ Dry bulb, wet bulb

What is Method 5?

Particulate matter is withdrawn isokinetically from the source and collected on a glass fiber

filter maintained at a temperature of 120 ┬▒14 ┬░C (248 ┬▒25 ┬░F) or such other temperature as

specified by an applicable subpart of the standards or approved by the Administrator for a

particular application. The PM mass, which includes any material that condenses at or above the

filtration temperature, is determined gravimetrically after the removal of uncombined water. Method 5 can be run in combination with other isokinetic methods (M23, M26A, M29, M202).

For more information and documents about Method 5, please consult the EPA’s Method 5 webpage.

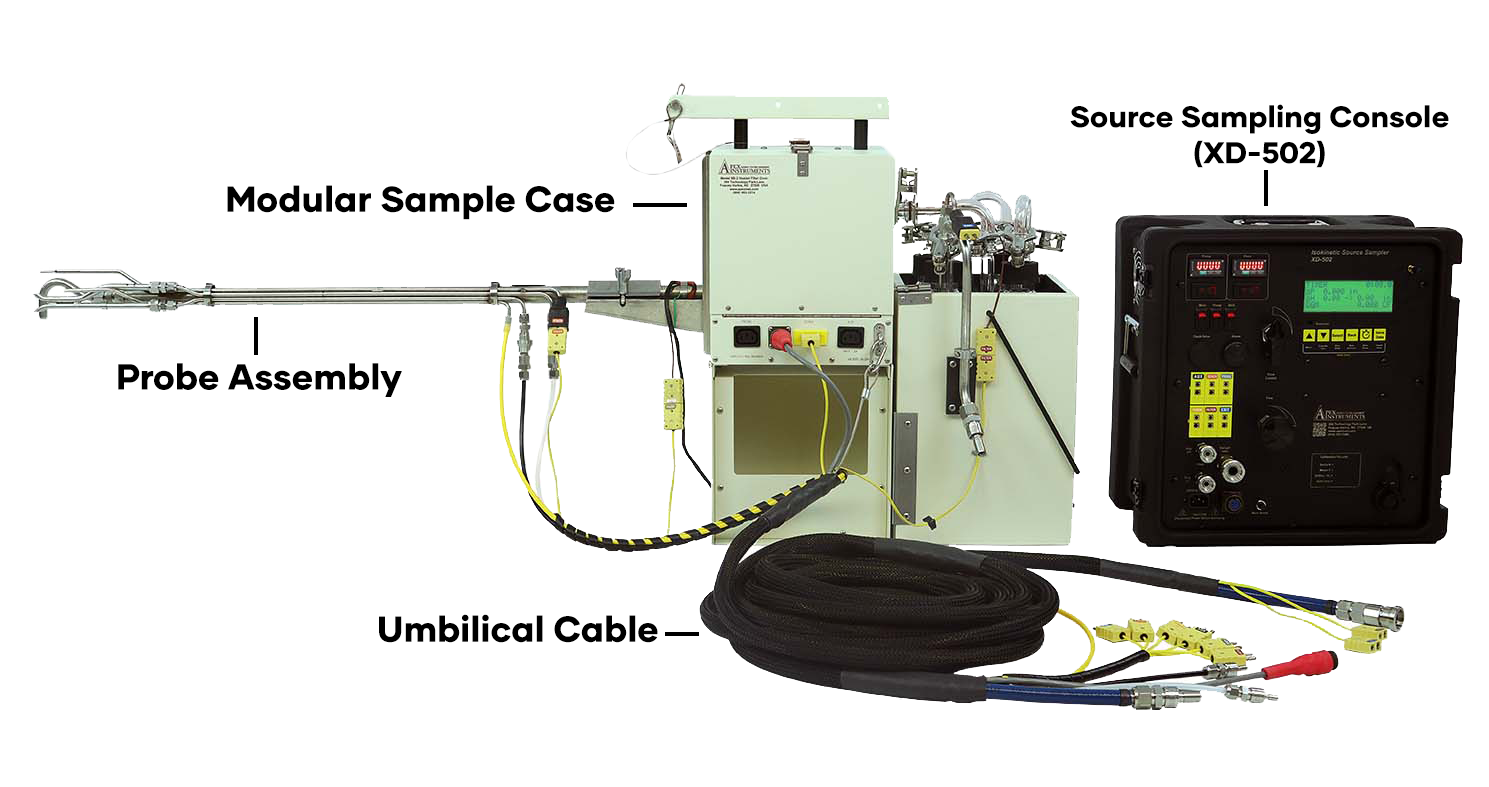

Information on Methods 5A-I can be found via the EMC Promulgated Test Methods Directory.

Apex Instruments offers a Method 5 Sampling Train. We also offer products for different versions of Method 5. If interested in Method 5 sampling, Apex Instruments works with our customers to make sure we are providing the correct products for your project and will provide you with a price quote. For any questions about our sampling train, please contact sales@apexinst.com.

Required Sampling Parameters for Method 5

ΓùÅ Sampling duration: typically 60-120 minutes

ΓùÅ Sampling rate: typically 0.50-0.75 dscfm

ΓùÅ Minimum sampling volume: 30-60 dscf (dependent on analyte MDLs and expected

concentrations)

Review 40 CFR Part 60 for minimum sampling duration, volumes and filter/gas temperatures.

Equipment needed for Method 5

ΓùÅ M5 Console

ΓùÅ Hot box (filter holder), which connects the probe and the sampling train with a heated filter.

Γùï Includes heating element to maintain filter temperature of 121┬░C (248 ┬░F)

Γùï Filter housing holds the filter within this box to prevent moisture

Γùï Offers flexibility for vertical and horizontal traverses

Γùï Insulated box maintains heat in various environments

ΓùÅ Impingers (condenser train) provide support and protection for glassware

Γùï Insulated case keeps impingers cool